What strategies do manufacturers use to reduce the cost of production?

In today's competitive market, manufacturers are constantly looking for ways to reduce the cost of production. This is especially true in the sporting goods industry, where margins are often razor-thin. To stay profitable, manufacturers have adopted a variety of strategies to reduce costs, including:

- Outsourcing: Many manufacturers have outsourced production to countries with lower labor costs. This can save companies a significant amount of money, but it can also lead to quality control issues.

- Automation: Manufacturers are increasingly using automation to reduce labor costs. This type of technology generally improves quality control.

- Value engineering: This process involves redesigning products to use less expensive materials or to simplify manufacturing processes.

- Economies of scale: Manufacturers can reduce costs by producing products in large quantities. This allows them to spread the fixed costs of production over a larger number of units.

- Lean manufacturing: This approach focuses on eliminating waste and improving efficiency throughout the manufacturing process. Can be vastly improved through automation.

By implementing these strategies, manufacturers can reduce the cost of production and improve their profitability. However, it is important to note that there is a trade-off between cost and quality. Manufacturers need to find the right balance between the two in order to stay competitive.

Related Questions

- What are the benefits of outsourcing production?

- Outsourcing can save manufacturers a significant amount of money on labor costs.

- What are the risks of outsourcing production?

- Outsourcing can lead to quality control issues if not managed properly.

- What is value engineering?

- Value engineering is the process of redesigning products to use less expensive materials or to simplify manufacturing processes.

- What are the benefits of economies of scale?

- Economies of scale allow manufacturers to spread the fixed costs of production over a larger number of units, which reduces the cost per unit.

- What is lean manufacturing?

- Lean manufacturing is a philosophy that focuses on eliminating waste and improving efficiency throughout the manufacturing process.

Related Hot-Selling Goods

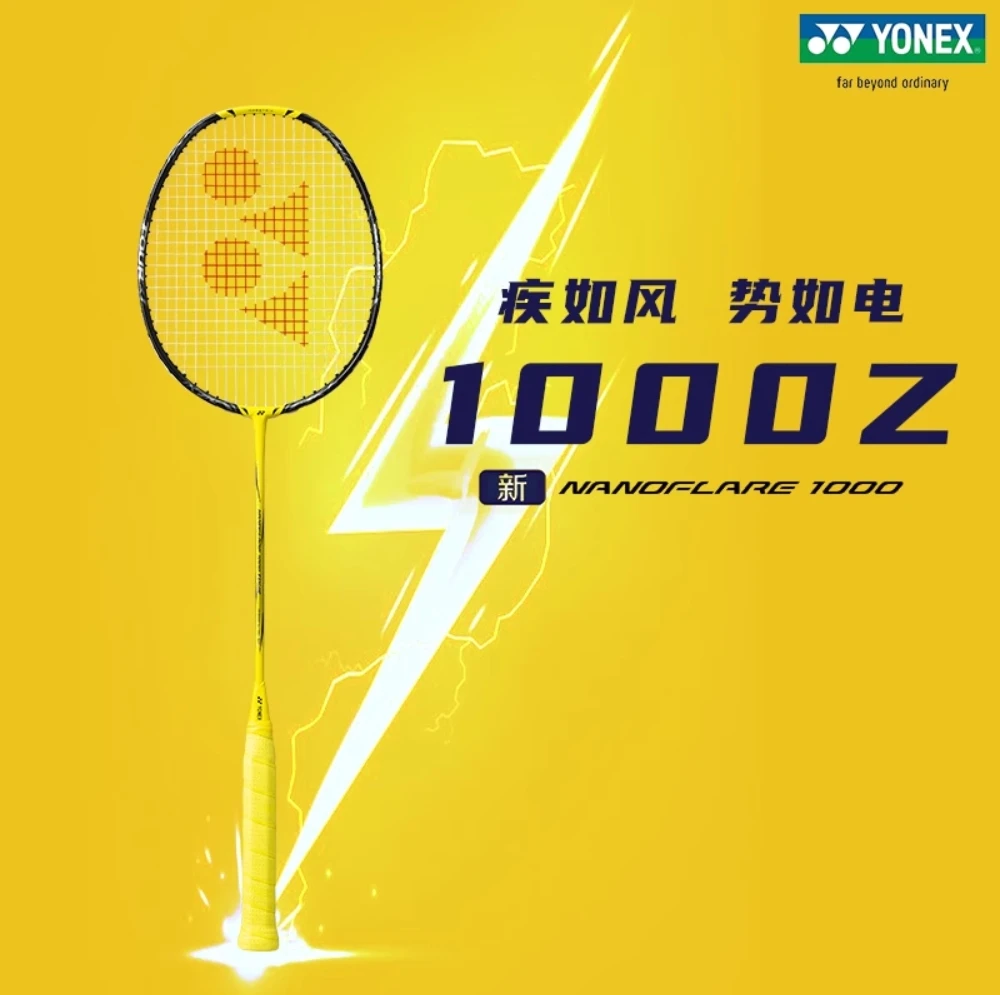

- YONEX Badminton Racket

- Victor Badminton Shoes

- Li-Ning Badminton Strings

- Carlton Badminton Shuttles

- Wilson Badminton Bags

Pre:Are there no state or federal government run radio and television stations in the United States

Next:What size of CO2 cartridge should I buy to refill a road bike tire 700x32mm to 100 PSI